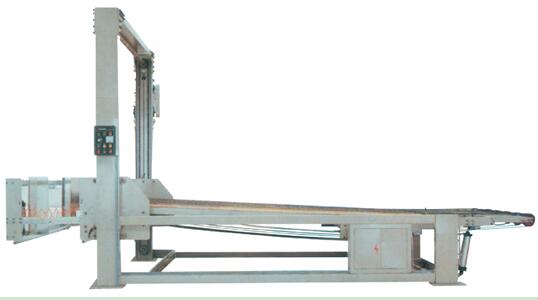

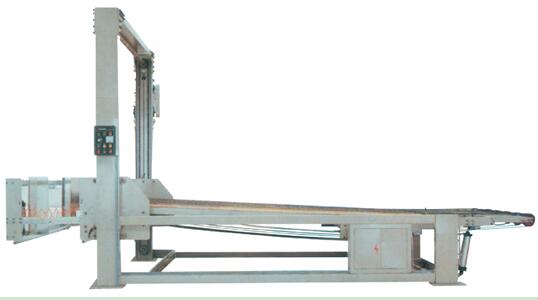

Model NO.: ZYKM1200x2400 Automatic Grade: Automatic Machine Economic Printing Speed (PCS/Min: 180 Min Paper Feeding Size (mm): 650×250 Max Printing Area (mm): 2400×1200 Catalog:

Carton Machine Specification: ZYKM 1200*2400 HS Code: 84418090 Type: Automatic Carton Making Machine Machine Max Speed (PCS/Min): 220 Max Paper Feeding Size (mm): 1200*2400 Paper Feeding Thickness Range (mm): 2.5-12 Standard Printing Forme Thickness (mm): 7.2 Trademark: Qisheng Origin: China ZYKM1200x2400

Fully Automatic Carton Making Machine

Video Link: http://www.56.com/u75/v_NTI5Nzc2NDg.html

Function Configure and Technical Parameter

I. Computer control operation unit

1. Memory return to zero: when machine is in working process, if need open the machine and doing wipe forme and change forme, when the machine closed, it can self recovery original position.

2. Controllable type anilox roller rising and falling: when some unit don't need printing temporary, can control this unit anilox roller don't need falling, thus don't need cleaning.

3. Position return to zero: complete appliance can make forme position return to zero, make the forme position in place one time, usually try to print two pieces can make the position correct.

4. The image of main electric motor displays vehicle speed, paper feed, even paper, separate pieces etc.

5. Monitor, display order design number, actual production number, fixed amount finished automatic stopping sheet feeding, anilox roller separate forme automatically.

II. Sheet feeding unit (one set):

Sheet feeding precision: ±1mm

1. Board on-off

1) Electric control board on-off adding alarm bells, while working continue ringing caution, ensure operating personnel safty.

2) Between each plane machine table, can install dead-stop switch, can stop plane machine table movement by innernal control, and ensure innernal operating personel's safty.

3) Gas dynamic type interlocking device.

4) Complete appliance always locked.

2. Dust suction system

1) Be equipped with absorbed crumbs dusting machine, and electric precipitation device, can remove impurity on the printing surface in quantity, increase printing quality.

3. Paper feeding roller

1) Upper paper feeding roller outside diameter isΦ142.68mm.

2) Solid drawn tube, package abrasive rubber, and make dynamic poise adjustment.

3) Downwards paper feeding roller Φ152.52mm embossing hard plating.

4) Paper feeding roller clearance scale adjusts by worm wheel, adjusting range 0-12 mm.

4. Second unit upward and downward paper roller roller.

1) Solid drawn tube, package abrasive rubber, and make dynamic poise adjustment.

2) Downwards paper feeding roller Φ152.52mm embossing hard plating.

3) Paper feeding roller clearance scale adjusts by hand regulation, adjusting range 0-12 mm.

5. Automatic paper feeding operating control

1) Formfeed left and right baffle, electromotion adjustment, back and forth baffle adjust by hand regulation.

2) Servo control advancing edge paper feeding system, can adjust input air according to cardboard bending degree.

Advancing edge paper feeding stype adopt servo motor drive. Idler wheel type paper feeding. Its feature is high paper feeding precision, mechanical vibration is less than other kinds of paper feeding machanism, small equipment failure rate, servocontrol system has no trouble happened while in regular service. Convenient maintenance, it has more usefultime than other kind of mechanical type cam advancing edge paper feeding mechanism.

III. Printing unit (rubber roller blowing ink system)

1) Outside diameter is Φ320.17mm (include forme outside diameter is Φ334.57mm), length is 2400mm.

2) Surface grinding, hard plating.

3) Activity static balancing regulation, operating stable.

4) Ratchet wheel stationary type roll forme axis.

5) Adopt hanging forme institution, installation easily, quickly, appliancable 10mm hanging forme item.

6) Load and unload printing forme, foot switch electromotion control positive and negative operating.

1. Printing impressing

2. Roller

1) Outside diameter isΦ152.2mm.

2) Steel tube surface grinding, hard plating.

3) Balancing regulation, operating stable.

4) Printing compression roller clearance scale adjust by hand regulation, adjusting range is 0-12mm.

3. Anilox roll

1) Outside diameter isΦ196.8mm.

2) Steel tube surface through Sanforized and spraying special ceramics laser graving ink cell, another unit is metal anilox roll.

3) Website is unanimous, inking even, durability, durable.

4) Prolongable useful life of printing forme and rubber roller, rag through Sanforized processing technic.

5)Ceramics roller screen density number: 400. Metal roller screen density number: 200.

4. Rubber roller blowing ink system

1) Outside diameter is Φ182mm.

2) Steel tube surface package corrosion resistant rubber.

3) Rubber roller high and middle special grinding, good spreading ink impact.

5. Phase position adjustment institution

1) Satellite gear institution

2) Digital display type phase position indication, make operating more convenient, direct viewing, accurate.

3) Printing phase position adopt PLC touch screen control and electromotion digital type 360 degree

Adjustment (operating, stop-operating can adjust). Adjusting phase position precision can reach to 0.10mm.

6. Printing ink circle, saving ink institution

1) Inking pipeline install saving ink cup and inking cup, and linking separately by two battery value, at the same time install cleaning pipeline

2) Air pressure type membrane pump, supply ink stable, easy to operate and maintain.

3) Printing ink trap value, filter impurity.

7. Printing phase position fixed device

1) Electric regenerative braking type brake mechanism.

8. Axial adjustment institution

1) Manual type axial adjustment institution

IV. Slotting unit (one group)

Slotting precision: ±1.5mm

1. Creasing Wheel

1) Diameter of axle is Φ128 mm, through two times grinding, surface hard plating, movement steady.

2) Creasing wheel clearance scale adjust by hand regulation, adjusting range is 0-12mm.

3) Grooving upside wheel adopt fine quality import Polyurethane.

2. Slotting knife file sideslip adjustment institution

1) Diameter of axle isΦ154mm, through two times grinding, surface hard plating, movement steady.

2) Slotting knife width is 7mm.

3) Alloy tool steel material through heat treatment, grinding jugged slotting knife, good hardness and toughness.

4) Alloy steel material through heat treatment, grinding trimming knife, knife edge sharp, high precision.

5) Creasing wheel, transmit paper wheel, slotting knife file sideslip position, adopt electromotion button synchro control.

3. Slotting phase position adjustment institution

1) Satellite gear institution.

2) Slotting front and back knife phase position adopt PLC touch screen control and electromotion digital type 360 degree adjustment (operating, stop-operating can adjust).

3) Slotting knife square transfer motion adopt electromotion adjustment (operating, stop-operating can adjust)

V. Die-cutting unit

1. Die-cutting roller

1) Outside diameter is Φ290mm, length is 2400mm.

2) Surface grinding, hard plating.

3) Activity static balancing regulation, operating stable.

2. Rubber Mat Roller

1) Outside diameter is Φ350mm, length is 2450mm.

2) Surface grinding, hard plating.

3) Activity static balancing regulation, operating stable.

3. Phase position adjustment institution

1) Satellite gear institution.

2) Digital display type phase position indication, make operating more convenient, direct viewing, accurate.

3) Slotting phase position adopt PLC touch screen control and electro motion digital type 360 degree adjustment (operating, stop-operating can adjust). The precision of adjustment can be 0.10mm.

4. Axial adjustment institution

1) Manual type axial adjustment institution

2) Rubber roll axial movement adopt electromotion adjustment (operating, stop-operating can adjust).regulating range is 50mm.

5. Rubber roller restoration institution.

1) Electromotion type restoration institution, renewable 2-3 times.

6. Die-cutting roller air lifter

1) Air-powered uplift and drop, convenient to die-cut, prolong the useful life of cushion.

7. Die-cutting cleaning waste institution

1) Motor driving cleaning waste belt and transport the waste produced by slotting and die-cutting outside the machine through the transport belt.

8. Differential adjustment institution

1) Ensure the quality of die-cutting, install governor mechanism outside the cushion roller gear; ensure the linear velocity of die-cutting roller and cushion roller is same.

VI. Stacking unit (one group)

1. Receiving paper arm

1) Include manual type and self-action operation.

2) Receiving paper arm driving belt, independent adjustment tightness, and can select and put to use the number of receiving paper arm voluntarily.

2. Lathe bed rising and falling

1) Mightiness chain drive

2) Stack height is 1600mm.

3) Lathe bed rising and falling motor attach brake function, lathe bed keep in a fixed position, will not glissade.

3. Receiving paper baffle

1) Air pressure action receiving paper baffle, when the cardboard stack to the height schedule in advance, receiving paper baffle automatic extend , hold the cardboard.

2) Backboard position hand regulation.

3) Plane wrinkle belt, prevent belt from glissade.

VII. Driver gear

1. Main drive gear

1) Adopt 20CrMnTi alloy steel, carburizing and quenching treatment, grinding gear.

2) Six grade precision ( same with car wheel box gear), operating smoothly, small noise, hardness HRC58-62, long useful life, almost can't fret in 10 years, can reach to long term print register.

2. Key connection ring

1) Adopt no key connection ring, can make axis and gear connect, haven't clearance when using big torque, make installation and maintenance more convenient, can make the machine long term drive and high precision, ensure print register.

VIII. Main technical parameter (5colors

Printing Slotting and Die-Cutting Machine)

| Standard | Model 1200*2400 |

| Machine max speed (pcs/min) | 220 |

| Machine economic printing speed (pcs/min) | 180 |

| Max paper feeding size (mm) | 1200x2400 |

| Min paper feeding size (mm) | 650×250 |

| Paper feeding thickness range (mm) | 2.5-12 |

| Max printing area (mm) | 2400×1200 |

| Standard printing forme thickness (mm) | 7.2 |

| Production Power (Kw) | 31.2 |

| Total power (Kw) | 35(according to printing group) |

IV. Motor list

l Paper feeding part

| No. | Name | Specifications | Quantity |

| 1 | Main motor (made in China) | 22KW (according to printing group) | 1 |

| 2 | Board open and shut (made in China) | 0.55kw 1/29 gear down motor | 1 |

| 3 | Left and right baffle adjustment (made in China) | 0.25KW 1/29 gear down motor | 2 |

| 4 | Push cardboard and back baffle adjustment | 0.55kw 1/29 gear down motor | 1 |

| 5 | Absorb paper assist blower 3KW motor | 3KW motor | 1 |

| 6 | Absorb crumbs and dust abatement blower (made in China) | 2.2KW motor | 1 |

l Printing part

| No. | Name | Specifications | Quantity |

| 1 | Phase position adjustment (made in china) | 0.37KW 1/30 gear down motor | 1 |

| 2 | Rubber roller operating (made in China) | 0.55KW 1/40 gear down motor | 1 |

l Slotting part

| No. | Name | Specifications | Quantity |

| 1 | Slotting back knife phase position (made in China) | 0.37kw 1/29 gear down motor | 1 |

| 2 | Slotting front knife phase position (made in China) | 0.37kw 1/29 gear down motor | 1 |

| 3 | Slotting knife left and right movement( made in China) | 0.55KW 1/29 gear down motor | 4 |

l Die-cutting part

| No. | Name | Specifications | Quantity |

| 1 | Phase position adjustment (made in China) | 0.37kw 1/30 gear down motor | 1 |

| 2 | Die-cutting repairing roller ( made in China) | 0.37kw 1/40 gear down motor | 1 |

| 3 | Cushion roller stretching ( made in China) | 0.75KW 1/2250 gear down motor | 1 |

| 4 | Die-cutting cleaning waste ( made in China) | 0.55KW 1/60 gear down motor | 1 |

l Stack part

| No. | Name | Specifications | Quantity |

| 1 | Transport belt ( made in China) | · 3KW governor motor | 1 |

| 2 | Lathe bed rising and falling (made in China) | 3KW 1/40 gear down motor (With brake) | 1 |

V. Other explanation

| No. | Name | Place of Production | Quantity |

| 1 | Bearing level | Haerbin, wafangdian ,Shengyang, some import | All |

| 2 | Ac contactor, thermorelay | Schneider, Iemens | All |

| 3 | Cushion roller stretching ( made in China) | 0.75KW 1/2250 gear down motor | 1 |

| 4 | Die-cutting cleaning waste ( made in China) | 0.55KW 1/60 gear down motor | 1 |

| 5 | PLC | German Iemens | 1 |

| 6 | Coder | Italy(ELCO) | 1 |

| 7 | Human-computer interface | Japan | 1 |

| 8 | No key connection ring | Made in China | All |

| 9 | Air-powered one way membrane pump | Made in China | All |

| 10 | Transducer | Japan (Anchuan) | All |

| 11 | Air- powered solenoid directional valve | Taiwan (AirTAC) | All |

Note: if the product parameter changed, the information is subject to changes without prior notice.

Contact us if you need more details on Printing

Slotting and Die-Cutting Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Slotting and

Die-cutting Machine、

Printing Slotting Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Printing Slotting&Die-Cutting Machine