Model NO.: DYA-81050G

Usage: Plastic Printing

Color & Page: Multi-Colour Printing Press

Print Flow Direction: From Left to Right

Printing Width Range: 600-1050mm

Plate Cylinder Dia.: 120mm-300mm

Max. Unwinding Dia.: 600mm

Tension Adjusting Range: 30-200n

Style: Intaglio Printing Press

Applicable Material: Plastic

Automatic Grade: Automatic

Structure: Rotary Printing Press

Printing Color Number: Eight

Max Mechanical Speed: 160m/Min

Plate Cylinder Width: 780-1100mm

Max. Rewinding Dia.: 600mm

Unwinder & Rewinding Air Shaft: 3"*1100mm

DYA-81050G Rotogravure

Printing Machine Main technical parameters:

Print flow direction from left to right

Printing color number Eight

Printing width range 600-1050mm

Max mechanical Speed 160m/min

Plate cylinder dia. 120mm-300mm

Plate cylinder width 780-1100mm

Color control precision Vertical: ±0.15mm (automatic register system)

Horizontal: ±0.2mm (hand control)

Max. Unwinding dia. ∮600mm

Max. Rewinding dia. ∮600mm

Tension adjusting range 30-200N

Unwinder &Rewinding air shaft 3"*1100mm

Air supply pressure 0.8Mpa

Press of impression 600kg

Doctor move range ±5mm

Dry method electrical heating

Dry power utilization 144kw

Main motor power 15kw

Total power: 185kw

Size: 17000×4300×3300(mm)

Weight: 30000kg

Base material & compound material

PVDC 35-60um PET 12-60um

OPP 20-60um BOPP 19-60um

CPP 20-60um NY 12-50um

PE 30-100um Lamination film 15-60um

And other materials are familiar with the above films.

Unwinder Parts

Double arm & double station whirling stand and wallboard stander

1 set

Web used 3" pneumatic shaft 2 pieces

Unwinder drive device: AC 4KW (ABB motor+ Vector transducer, Yaskawa, Japan +Encoder, Omron Japan) 2 pieces

Auto splicing device-including cutting blade 1 set

Dance rolls tension inspecting device (including Fujikura, Japan low friction cylinder, Shanghai, precision

Regulation resistance, SMC, Japan precision air pressure regulator) 1 set

Web turning AC gear down motor 0.75KW 1 set

Web diameter inspection &alarm device 1 set

Operation control box 1 set

Infeed Part

Cast iron wallboard and transom stander 1 set

Steel roller ∮125mm 1 piece

Rubber roller ∮120mm NBR (70°-75A) 1 piece

AC2.2kw vector motor (SIEMENS motor+ Vector transducer, Yaskawa, Japan +Encoder, Omron Japan) 1 set

Dance roll tension inspecting device(including Fujikura ,Japan low friction cylinder, Shanghai ,

precision regulation resistance ,SMC ,Japan precision air pressure regulator) 1 set

Operation control box 1 piece

Printing unit

Printing set composed of cast iron wallboard transom 8 sets

(2200mm*500mm*70 mm ,The length is 1600mm between each unit)

Transmission device and shaftless Pneumatic cone for install plate cylinder 8 sets

Drive of printing units AC15KW (SIEMENS motor+ Yaskawa, Japan Vector transducer) 1 set

Vertical photo electricity auto color control 7 sets

Pneumatic doctor blade device 8 sets

Motor of doctor device (0.37KW) 8 sets

Vector transducer of doctor device (Yaskawa, Japan ) 1 set

Ink plate elevating 8 sets

Printing ink cycle device 8 sets

Impression rubber roll 75º-80º 8 pieces

Register around error adjust device 8 sets

Impression cylinder63*125 16 pieces

Operation electric box 8 pieces

Dry unit

Separate sirocco dry box (Nozzle 8pieces, material length 1400mm) 7 pieces

The last dry box ((Nozzle 9 pieces, material length 1600mm) 1 piece

Separate heating box 8 pieces

AC 2.2KW sirocco blower 7 pieces

AC 3KW sirocco blower 1 piece

Stainless steel electrical heating pipe 3kw/piece 48+3 pieces

Temperature control device (Fuji, Japan) 8 sets

Cooling unit

Aluminum alloy water cooling roll ∮150mm 8 pieces

Water tank 8 sets

Pipe tie-in of enter water 8 pieces

Out feeding Unit

Cast iron wallboard and transom stander 1 sets

Steel roller ∮125mm 1 piece

Rubber roller ∮120mm NBR(70°-75A) 1 piece

AC2.2KW (SIEMENS motor+ Vector transducer, Yaskawa, Japan +Encoder, Omron Japan) 1 piece

Dance rolls tension inspecting device (including Fujikura, Japan low friction cylinder,

Shanghai Precision regulation resistance, SMC, Japan precision air pressure regulator) 1 set

Operation control box 1 piece

Rewinder unit

Double arm& double station whirling stand and wallboard stander 1 set

Web used 3" pneumatic shaft 2 pieces

Rewinder drive device: AC 4KW (SIEMENS motor+ Vector transducer, Yaskawa, Japan +Encoder, Omron Japan) 2 pieces

Dance rolls tension inspecting device (including Fujikura, Japan low friction cylinder,

Shanghai precision regulation resistance, SMC, Japan precision air pressure regulator) 1 set

Web turning AC gear down motor 0.75KW 1 piece

Auto non-stop exchange web and splicing device-including cutting blade 1 set

Web diameter inspection &alarm device 1 set

Operation control box 1 piece

Stander

Guide roller 80mm 100mm surface is anodic treatment

Counterbalance at outside dia. ≤5g

Guide roller length 1100mm

Wallboard thickness 70mm

Space between each color 1600mm

Screw step 36mm

Electric control system

Main control system PLC Panasonic, Japan 1 set

Vector transducer Yaskawa, Japan 8 pieces

5.7" black and white interface Taiwan 2 pieces

Separate electric control box 1 set

Low voltage electrics 1 bulk

Register system

Auto register control system (Huamao,China) 1 set

Video inspecting device (Huamao,China) 1 set

Register remote control box 7 pieces

Electrostatic elimination system

Self discharge eliminator (wuxi ,China) 10 pieces

Accessories

Trolley for Material 1 set

Tools and tool box 1 set

Ladder 1 set

User should install assorted device

Electrical power: triphase five-wire system 380V

Air supply: Pressure more than 8KG/CM2 dry air

Water supply: Pressure more than 2KG/CM2

Exhaust fan: 11kw, wind pressure: 1200Pa, flux 13000m3/h

DGF-1050B lamination machine

1, Main technical parameters:

Applicable base materials:

Cellophane paper 20-30um PET 12-60um

OPP 20-60um BOPP 20-60um

CPP 20-60um NY 12-50um

PE 30-100um Aluminum foil 7-40um

Laminating width: 600-1050mm

Laminating trend: from left to right

Mechanical Speed: 130m/min

First unwinder dia.: ∮600mm

Second unwinder dia.: ∮600mm

Rewinder dia.:∮600mm

Rewinder & unwinder paper core: ∮76(inside dia.)

Rewinder & unwinder shaft: Air shaft

Coating roll dia.:∮165mm

Screen density: 80-180 wire/inch (can be decided according to buyer's requirements)

Tension enactment range: 3-30kg

Tension control precision: ±0.5kg

Oven length: 9000mm

Max temperature in the oven: 100ºC (environment temperature 20ºC)

Max temperature of lamination roll: 80ºC (environment temperature 20ºC)

Dry method: electricity heating

Lamination pressure: 2000kg

Total power: 165kw (50HZ, 400V)

Size::11500×3800×4200mm

Weight: 13000kg

2, Machine configuration and related parameters

2.1Unwinder Parts(No1)

Single type Single arm, & Single station wallboard stander 1 set

Web used 3" pneumatic shaft 1 piece

Unwinder drive device: 5KG power brake (Taiwan) 1 set

Press sensor (30KG) 1 set

EPC device (made in China) 1 set

Operation control box 1 set

2.2Unwinder Parts(No2)

Two station wallboard stander 1 set

Web used 3" pneumatic shaft 1 piece

Unwinder drive device: 5KG power brake (Taiwan) 1 set

Press sensor (30KG) 1 set

Operation control box 1 set

2.3Coating unit

Coating set composed of cast iron wallboard transom 1 set

Mezzotint roll (∮165mm*1100mm) 1 piece

Impression roll (∮120mm*1100mm NBR 650-700A) 1 set

Double cylinder for Doctor Blade 1 set

Coating roll drive: AC4kw vector motor+ Vector transducer, Yaskawa ,Japan 1 set

Automatic circle system (pneumatic pump) 1 set

Stainless steel glue pan and up and down device 1 set

Press sensor (30KG) 1 set

PLC module 1 piece

Operation control box 1 set

2.4Oven units

Totally closed heat preservation oven (three sections, Total length 9000mm) 1 set

Separate temperature control oven 3 sections

Temperature control show apparatus 3 sets

Preposing air draft cover and air discharge pipeline 1 set

Cylinder for oven pneumatic opening 3 sets

Guide roll in oven 18 pieces

Flat nozzle 18 pieces

Dry heat origin electric heating: 45KW/ section and bracket 3 sections

Blower power: 2.2kw/Set 3 Sets

EPC (made in China) 1 set

Ladder 1 set

2.5Lamination Unit

Cast iron wallboard and transom constitute the lamination unit 1 set

Mirror face lamination steel roll Φ270mm×1300mm 1 piece

Pressing in rubber roll Φ130mm×1300mm 80°-85°(A) 1 piece

Drive motor 7.5kw AC vector frequency conversion motor 1 set

AC5.5KW Transducer, Yaskawa, Japan 1 set

Electric heating device for lamination roller (power 9kw heating for oil) 1 set

Pneumatic pressing in device 1 set

Temperature control apparatus 1 set

Touch screen 1 set

Operation control box 1 piece

2.7Cooling unit

Cooling roll dia. ∮190mm

Hydraulic pressure >3kg/cm²

Water temperature below 25ºC

2.8Rewinder unit

Single station and wallboard stander 1 set

Web used 3" pneumatic shaft 1 sets

Rewinder drive device: AC4kw vector motor+ Vector transducer, Yaskawa, Japan 1 set

Press sensor (50KG) 1 set

Rewind coning control 1 set

Web dia. Inspecting and Max. Dia. alarm 1 set

Operation control box 1 piece

2.9Electric control system

Electric main control box 1 set

PLC control system 1 set

5.7. inch man machine 1 piece

On-off power 1 set

Low voltage electric 1 bulk

2.10Illuminating system

Full set safety explosion-proof light 4 pieces

2.11Air circuit system

Main pneumatic element use Airtac 1 bulk

2.12Electrostatic elimination system

Self discharge eliminator 4 pieces

2.13 The Software: made by seller self

3, User should install assorted device

Electrical power: triphase five-wire system 380V

Air supply: Pressure more than 6KG/CM2 dry air

Water supply: Pressure more than 2KG/CM2

Exhaust pipe and Exhaust fan: 5.5kw, wind pressure: 1000Pa, flux 78000m3/h

Cooling water pipe

Groundwork and material of install machine

And other equipment for installation.

Device type:KFQ-1300A

Slitting Machine

Article1, Applicable Materials

BOPP,CPP,PET and laminated film and other materials.

Article 2,Main technical data

1. Maximum Unwinding Diameter: 600mm.

2. Maximum Winding Diameter: 400mm.

3. Maximum width: 80-1300mm.

4.Maximum speed:10---180m/min(different material different speed)

5. Rectify precision;≤ ±0.5mm.

6. Total power:≈5kw.

7. Paper core inner diameter:Φ76mm.

Article3, Machine sketch map(attached)

The device type of light-activated slitting machine is KLF-PA. The machine is vertical fluctuation of rewinding type. This graph is preliminary design of lateral view. In the actual design manufacturing process, on the premise of ensuring technical parameters, local structure may be changed.

Article 4,Main configuration

1. Unwinding adopts feeding with axis with three inches convex key type flatulence axis.

2. The unwinding frame has 5kg magnetic powder brake(LanLing Haian),manual control unwinding tension.

3. LPC of on/off control

4. Special motor of AC 4kw drives feeding motor with variable frequency controller (ENC)

5. Active roller and pneumatic traction press roller.

6. Razor cutter, five sets of blade cutter.

7. Blow edge device

8. Upper and low rewinding shafts execute tension with 5kg magnetic powder clutch (LanLing Haian), manual control rewinding tension.

9. Rewinding press roller device.

10.Three inches(76mm)rewind shaft ,convex key type flatulence axis.

11. Guide rollers adopt aluminum alloy guide roll and rubber roller combined, all guide rollers are by dynamic balance processing.

12. Pneumatic components

13. Timing belt

14. Bearings (Harbin)

15. Electrical components of the machine are imported components or domestic famous brand.

16. Two times temper treatment for frame and base.

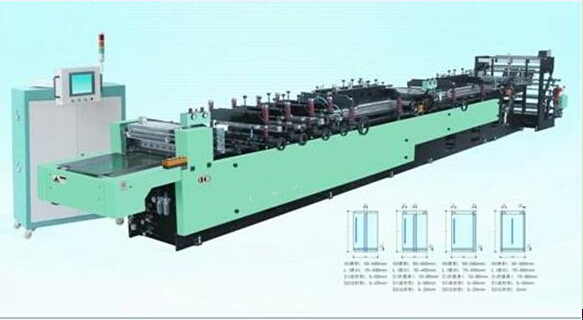

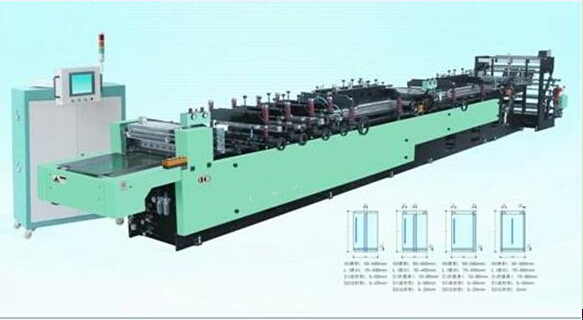

| 420- Automatic Center Seal Bag & Four Side Seal Bag Making Machine |

Contact us if you need more details on Plastic Printing Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Printing Machine、Rotgravure Printing Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Auxiliary Machinery