Model NO.: WJ-150-1600

Automatic

Production Line: Assembly

Automation: Automation

Rhythm: Flow Production Line

Design Speed: 150m/Min

Expiry Width: 1600mm

Reel-Paper Grade: Not Less Than B

Face Paper: 150-200G/M2

Corrugated Paper: 105-180G/M2

Trademark: QS

Origin: China

Transmission Type: Flexible

Certification: ISO, CE

Flexible Production: Intelligent Manufacturing

Production Scope: Product Line

Economic Speed: 100m-120m/Min

Length: See Your Groundsill Drawing

The Moisture Rate of Reel Paper: 11%+/-1%

Liner Paper: 150-200G/M2

Category: Cardboard Production Line

Specification: 150-1600mm

HS Code: 84418090

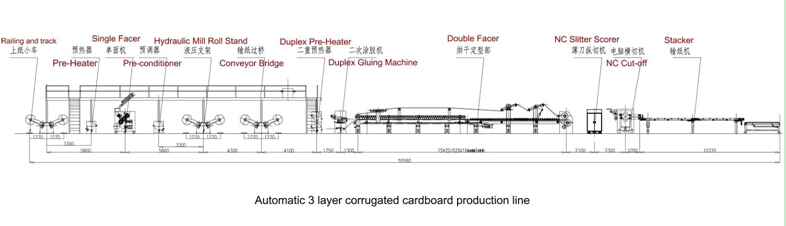

WJ150-1600 5layer

Corrugated Cardboard Production line

Main technology parameter of production line

NO: WJ100 1600 5 Layer corrugated carton production line:

1. Design speed: 150m/min

2. Economic speed: 100m-120/min

3. Expiry width: 1600mm

4. Length of production line: (base on the groundsill drawing).

Note:

The paper which test the speed of production line according to the request, as follows

*Reel-paper grade not less than B.

*The moisture rate of reel paper:11%±1%

*Face paper: 150-200g/m2

*Liner Paper: 150-200g/m2

*Corrugated paper: 105-181g/m2

5. Flute: A, B, C, E flute ( as per the clients' sample),Please check the flute height as below

| Characteristics of Flute |

| Flute Type | Flute Height(MM) | Qty/300mm length | Note |

| A | 4.6-4.9 | 34+/-2 | Usually for lining |

| C | 3.6-3.9 | 38+/-2 | Usually for lining |

| BC | 3.2-3.3 | 44+/-2 |

|

| B | 2.6-2.9 | 50+/-2 | Usually for Printing |

| D | 2.0-2.2 | 78+/-2 |

|

| E | 1.5-1.8 | 88+/-2 | Usually used for color printing |

| 1.1-1.5 | 98+/-2 |

| F | 0.8-1.0 | 128+/-2 |

|

6. Voltage and Current frequency: 380V, 50Hz,three-phase four-wire system(or as per clients country standard)

7. Equipment direction: Left or right transmission will be according to client's request.

Note: Customer's self-provided part:

1. Air pipeline and Glue liquid pipeline

2. Power supply, the wire link to operate box and circuitry pipeline

3. Water source, water feeding pipeline and barrel.

4. Groundsill plane installation project for water, electricity and air

5. The material of paper, corn starch, Caustic soda for industry and borax etc.

6. The engine oil, lubrication, hydraulic oil, grease and high temperature lubricating grease for equipment.

7. The food, hotel for technicians of installation and test. And provide the erectors to assist in installation.

8. Boiler 2T supply by customer.

WJ100-1600 5Layer

Corrugated Cardboard Production Line Configuration List

| No. | Machine name | Qty | Remarks |

| 1 | Mill Roll Stand | 5 | Full hydraulic control, pneumatic control brake, inner expansion chuck, hydraulic station adopt Taiwan product |

| 2 | Railing and track | 10 | Include railing and track. |

| 3 | Pre-heater (Facer paper) | 1 | Diameter 600mm,electric adjust wrapping angle |

| 4 | Single Facer | 1 | Corrugating roll C flute, diameter 280mm, adopt 48CrMo alloy steel, main bearing adopt imported NSK brand. |

| 5 | Pre-conditioner | 1 | Diameter 600mm, electric adjust wrapping angle |

| 6 | Single layer bridge conveyer | 1 | Frequency adjust wind adsorption, electric correct error |

| 7 | Dual pre-heater | 1 | Diameter 600mm, electric adjust wrapping angle |

| 8 | Gluing Machine | 1 | Gluing roll diameter 318mm, main bearing adopt NSK brand |

| 9 | Double facer | 1 | Heating plants 15pcs, surface do treated and chromed, pneumatic tension, hydraulic lift-down, include cotton belt |

| 10 | Main drive | 1 | Independent reducer box, gimbals (cardan joint) driving. Corrugating roll diameter 768mm |

| 11 | NC slitter scorer | 1 | 5 blade 8 scorer. |

| 12 | NC cutting

Machine | 1 | Adopt imported servo driver, paper cutting precision 1mm when the speed average |

| 13 | Stacker | 1 | Wide belt transmission cardboard |

| 14 | Glue making system | 1 | Include main pot 1 set, carrier pot 1 set, and storage pot 1set, include glue station pump, single facer glue pump and gluing machine glue pump. Circle supply glue, pipeline provided by customer |

| 15 | Pneumatic system | 1 | Include air-water separator, gas storage pot and air-compressor, pipeline supply by customer. |

| 16 | Electric system | 1 | Whole line main motor frequency adjust speed, main electrical part adopt Schneider |

| 17 | Steam system | 1 | Adopt imported brand valve and drain valve, pipeline provided by customer |

Hydraulic Mill Roll Stand RS-1500H

This machine is used for supporting and outputting device,

Supply the paper to the machines and for production line.

Specification:

1. Working width: Max: 1600mm

2. Paper roller diameter: 2 side Ø1500mm, Min clamp paper diameter: Ø350mm

3. The lift-down arm adopted with cast iron curve structure, slinky, firm and steady.

4. Lift-down, clamp-loosen and left-right move are control by hydraulic cylinder.

5. Lifting Clamp arm, clamp and open, left & right sidesway: Equipped with 5HP*4P oil hydraulic system.(Taiwan brand). And one oil pump, oil pressure valve. Oil hydraulic cylinder spec.: 4x Ø63*ST750(Left and right) and 2x Ø100*ST475(Up and down).

6. Tension control: pneumatic brake, the function of brake is good, with air-pressure valve, pressure regulating valve and manometer to show details when running.

7. Whole machine adopt hydraulic control, easy to operate, low fault rate.

8. The chuck adopts inner expansion top design; avoid broking the core of paper roll.

Main

Spare Parts:

1. Hydraulic system adopt Taiwan brand.

2. Electrical main adopt SCHNEIDER brand.

3. The chuck Chinese brand.

4. Bearing adopt Chinese best brand(HA,LO,WA)

Railing for reels

Structure:

1. Moving paper roller, light and flexible

2. Rail way is on the ground, main structure is welded with 16 channel steel, firm and durable

3. The upper steel plate will be welded after installation on the premise.

SF-280S Single facer

Description:

Single facer is design for producing single-face corrugated paper, the medium process into wave-paper, and past glue on the top of flutes, stick with liner become into single-face corrugated paper.

Technical Parameter:

1. Working width: Max:1600mm

2. Max design speed: 150m/min

3. Max work speed: 100~120m/min

(Paper standard: no less than B grade, face paper 140~175g/,corrugated paper 100~125g/m2)

Total power: 53.45kw

Driven motor: 37kw

Adsorption fan power: 15kw

Clearance motor: 100w 3sets

Adjust gluing area motor: 200w 2sets

Gluing roller automatic rotary motor 750w 1set

Steam pressure: 10~14bar

Flute type: UV type, corrugating roller diameter Ø360MM. One pair two pcs

Corrugating roller raw materials: 48CrMo alloy steel, made in Shanghai.

Flute: A, C, B or E could required by buyer.

Pressuring roller: Ø370MM one pcs, made in special hard steel, surface do grinding and chromed.

Gluing roller: Ø250MM, one pcs, surface do grinding, embossing and chromed.

Doctor roller: Ø140MM, one pcs, surface do grinding, chromed and do polishing.

Specification:

1. Upper corrugating roller lift-down controller by two hydraulic cylinders.

2. Cylinder with magnetic valve button & hydraulic station control pressure roller

3. Gluing group: Advance and retreat of the glue roller house is control by two pneumatic cylinders.

4. Adjust glue thickness: Quantity of pasting glue and control glue is control by the clearance between glue roller and doctor roller adjustment and the inter-face appear control, figure show gluing details.

5. Adjust advance and retreat of glue roller and pressure roller clearance: The electric motor drive cam micro-adjust, and display the adjusting quantity on inter-face by the motor.

6. Adjust pressure roller clearance: The electric motor drive cam micro-adjust, and display the adjusting quantity on inter-face by the displacement sensor.

7. Main drive part: Main drive with the separate gear box to shift drive, gear is made from high quality alloy steel and the dip oil type, low noise, long life.

8. Driving part details: The gear box transfer the kinetic energy to the three rollers (upper, down corrugated roller and pressure roller) through the universal transmission shaft. The structure ensures the stable performance, easy and fast to maintenance.

9. Gluing roller idle running part: gear reducer motor, avoid glue dry on roller when machine paused.

10. Add three steam turning tie-ins, steam tube and one backwater equipment.

11. The iron blank on top of machine can separate disconnect to clean garbage inside, not need disconnect whole machine.

12. The axis of upper, down corrugated roller and pressure roller adopt the resistant high temperature oil to lubricate

Main spare parts brand:

1. Corrugated roller, pressure roller bearing adopt NSK Japan brand, total 12 pcs.

2. Gluing roller and fixed gluing roller bearing adopt NSK Japan brand, total 4 pcs.

3. Electrical, main adopt ABB, SCHNEIDER, SIMENS brand.

4. Motor, main adopt Taiwan Teco brand

5. Converter, main adopt Taiwan DELTA brand

6. PLC adopt Taiwan DELTA brand

7. Gluing channel material adopt stainless steel

8. Reducer gear box, the gear material is 40Cr,high precision grinding

Pre-heater(for facer paper, corrugated paper and Duplex heating)

Description:

This machine is used for heating liner (pre-conditioner for corrugated paper), and dry to control temperature and humidity of inner (pre-conditioner for corrugated paper)

Specification:

1. Working width: Max1600mm

2. Diameter of heating roller: 900mm

3. Heating roller adopts professional manufacturer product, passed the nation pressure vessel text.

4. Wrap roller: Ø110MM-2sets, one fix roller, and other one floating roller.

5. Motorized wrap angle can be suit for different speed.

6. Adopt 1/2HP motor add worm gear reducer 1set, gear drive type.

7. Electric motor driving the pre-heater roller rotary when running machine.

Main spare part brand:

Electrical, main adopt ABB, SCHNEIDER, SIMENS and so on brand.

Adjust wrap reduce speed motor Chinese brand

Duplex pre-heater

Description:

This machine is used for heating liner (pre-conditioner for corrugated paper), and dry to control temperature and humidity of inner (pre-conditioner for corrugated paper)

Specification:

1. Working width: Max1600mm

2. Max design speed: 150m/min

3. Max work speed: 120m/min

4. Diameter of heating roller: 600mm

5. Pre-Heater dum & warp rolls are hard chrome.

6. Drum is movable with paper to make paper heated and evenly & reduce paper break.

7. Electric wrap arms allowing a greater range of wrap angle from 50~270 degree.

8. Heating roller adopts professional manufacturer product, passed the nation pressure vessel text.

9. Wrap roller: Ø110MM-2sets, one fix roller, and other one floating roller.

10. Motorized wrap angle can be suit for different speed.

11. Adopt 1/2HP motor add worm gear reducer 1set, gear drive type.

12. Electric motor driving the pre-heater roller rotary when running machine.

The main appliances adopt the Schneider Brands

The main motors adopt the Taiwan Brands

Bridge Conveyor BC-200

Description:

This is conveyer bridge is designed for transport single-side corrugated paper by the top of the single facer to the multiplex pre-heater.

Machine Introduction:

1. Adopts suction tension device, use high pressure adsorption motor to suction the single face paper, make it flat to input the next process.

2. Installing two operate board could be adjust on the bridge and ground.

3. Paper receiving device adopts independent frequency conversion control, manufacture enough single face paper to wave type, and make sure enough storage of single face paper, to keep in-phase different speed in manufacture.

4. With feeding paper frame on the bridge and two conveyer belt to transport the single face paper to the bridge, forming wave type to storage the single face paper.

5. The Automatic adjust the position of single face paper, reduce waste paper ratio of the manual operation.

6. Equipped block part, in order to single face paper stack well on the bridge when the machine in high speed.

7. With two sets of operational panels and it could be operated at upper bridge or lower bridge

8. With safety rails at two sides and staircases.

The main appliances adopt the Schneider Brands

The main motors adopt the Taiwan Brands

Gluing Machine GA-318D

Description:

Double gluer machine is pasting glue on top of single-side corrugated paper. When you operate, don't overstep the designing bound.

Machine Introduction:

1. Max work width: 1600mm

2. Max work speed: 150m/min

3. Total power:11.4kw

*upper driven motor 5.5kw

*upper gluing roller gap adjustment motor 100w 1 set

*upper pressure roller gap adjustment motor 100w 1set

4. Gluing roller diameter: φ318-1pcs, steel pipeline product, surface do special grinding and hard chromed.

5. Doctor roller diameter: φ160---1pcs,steel (S45C),grinding and do hard chromed.

6. Pre-heater roller diameter: φ400 (upper)- single face paper used(1pcs),φ400(lower)- face paper use(1pcs),steel product, each roller all pass China Pressure Vessel test, with certificate.

7. Pressing roller: φ130-1pcs carbon steel, do grinding and polishing treatment.

8. Leading paper roller: φ110-4pcs, steel product, hard chromed and polishing treatment.

9. Pneumatic cylinder: 2sets control the pressing roller lift and down, the gap adopts electromotion adjust.

10. Motor made in Taiwan, adopts frequency transducer to control the speed, ensure same speed with double facer, idle running make non-dry glue when stop the machine.

11. Gluing thickness can be according to speed PLC control automatic adjustment also can be adjusted by electromotion.

Main Parts:

The bearings of Up layer gluer and frictioning roller: Japan NSK

The bearing of Down layer gluer and cooling roller: Japan NSK

Appliance: ABB and Schneider

Electrical Motor: Chinese Brands. Such as Chengbang, etc.

Inverter: Taiwan Taida

Double Facer DF-120(pressure roller type)

Description:

Double facer is corrugated paper enter into hot plants heating and molding after pasted glue, and become board after cooling.

A. Heating section & Heating plants:

1. Heating plants: steel product, dimension: 150MM*520MMTotal 15pcs heating plate.

The surface experienced grinding, chrome plating and polishing treatment, clean up the within-stress after jointed hot plates, and that ensure heated temperature equably within 0.5MM.Passed the nation pressure vessel text, add the pressure vessel certification.

2. Front input pressing roller: Ø60*L2300MM steel product.

3. The hydraulic pressure system automatic control the hang-board to drive pressing roller lift-down.

4. Install lift-down gear box 12 pcs.

5. Install hydraulic system (5HP*4 motor, oil-board and magnetic valve.

6. Hydraulic cylinder: Ø125*ST250MM.

7. Main structure channel steel made in 36# steel

8. Steam input pipe:Ø4 seamless pipe(main machine part supply by manufacturer, out of machine part provided by buyer)

9. Steam output part: Ø3 seamless pipe(main machine part supply by manufacturer, out of machine part provided by buyer)

10. With one canvas belt around regulator, convenient to operate.

11. Steam enters part and exit part adopts "S" type, ensure heating plants temperature stable and well-distributed.

12. Temperature control independent control, suit for different manufacture speed.

13. Lifting roller part with high efficiency, stable and safe.

B. Cooling section:

1. Upper pressure roller: Ø60*L2360MM,steel product

2. Lower running roller: Ø60*L2360MM steel tube product

3. With one upper canvas belt automatic correct error device, pneumatic control tension device 2sets.

4. With one lower canvas belt automatic correct error device one set.

5. Lifting belt type could be choosing hydraulic type.

Main Driving part:

1. Main motor drive upper and lower driving rollers by cotton belt, makes the carton to next process.

2. Steel rollers covered with high quality wear-resistant rubber with "V" stripe.

3. The driving gear box adopts oblique gear structure, high strength, low noise, and convenient for maintaining.

4. Easy to inject lubricate oil for the gear box.

5. Upper roller diameter Ø768MM

6. Lower roller diameter Ø768MM

7. Main power: 55kw, frequency motor with transducer.

The main appliances adopt the Schneider and other famous Brands in world.

NC Slitter Scorer

Machine introduction:

1. Whole machine control system adopt Taiwan origin computer and PCL control.

2. A memory of 999 orders, which could select any order to produce as requirement at the working time.

3. Automatic synchronizes with the corrugators.

4. Automatic knife grinding system can realize to repair the knife while the line is running without any stop. Knife grinding device also could enactment the interval meters according to material and edge condition.

5. Blade and scorer adjusts automatically, and have electro motion fine regulating function.

6. Scorer depth adjustment controlled by computer, match manual button for fine regulation

7. Upper and lower scorer wheels controlled by air pressure and it will not need to cutoff the cardboard during order exchanging.

8. Three score types for single wall, double wall and triple wall, which can also press different thickness in order to cardboard print.

9. It is easy to change the knife, every knife matches adjustable automatic grinding lubricate device, record the cutting length independently. Consumers can enactment the grinding time and interval time according to different paper material and cutting space condition.

10. 1mm high quality knife cut the cardboard with a high speed ensure the cut edge clean and beautiful which it is better for printing.

The main appliances adopt the Schneider Brands

The main motors adopt the Taiwan Brands

NC Cutoff NC-120

Machine Introduction

This machine is with steady structure, high tension and cutting precision. Adopt high precision cutting frame, driving part adopts AC servo motor and industry computer system. Easy operate.

Technical parameter:

1. max cutting width: 1600mm

2. Frame structure, good design in seat board, steady and good beauty.

3. Driving gear raw materials: SCM21 alloy steel, special manufacture process, harden and precision grinding, hardness about HRC58-~60,precision JIS1 grade-0 group.

4. max design speed: 160m/min, normal work speed: 150m/min

5. This machine adopts industry computer system, PLC and computer composed, easy to operate.

6. Adopt AC servo motor drive, drive part adopt import product.

7. It could be manage by whole system, non-stop machine to change cutting order.

8. Adopt helix cutting blade, small cutting strength, high precision.

9. Special materials blade, good structure of blade and frame, long time work life.

10. High precision gear drive, do many process and heating process, small gap and work steady.

11. High cutting precision, steady speed ≤±1mm,change speed ≤±1.5mm;

12. Standard type single blade machine.

Material and Purchased Parts:

Up and down cutter shaft: SC45

Knife: W18crv5Co5

Gear: 40Cr accurate grinding treatment

Main Driver motor (AC Servo) Power: 30kw 1 unit

Feeding motor: 3.7kw power 1 unit

Oil pump motor: 0.19kw 1 unit

Bearings: NSK

The main appliances adopt the Schneider Brands

The main motors adopt the Taiwan Brands

Corner Stacker

1. Adopt frequency motor, speed could be change suit for different manufacture speed. Improve work efficiency

2. Each belt installs independent drive, suit for different manufacture and different cutting length and stack.

3. Horizontal part rolls adopt chain feeding, work steady and low noisy, easy to maintenance.

4. Stack table pneumatic separately control, back- baffle could do electric adjustment, suit for different cutting length, ensure good stack.

5. Running speed: 150m/min

Technical Parameter:

Max. Tipping length: 2300mm

Max. Mechanical speed: 150m/min

Operation speed: 120-140mm

Air source pressure: 0.6-0.9Mpa

Total motor power: 8.9kw

Structure Features:

Air powered stacking & collecting cardboard

Electrical transverse output

Wide conveying belt for vertical collecting paper

The switch controls the cardboard's shifting out when the height or quantity of cardboard is up the standard.

Conveying belt motor: 3.7kw

Transverse rowing paper motor: 1.5kw

The main appliances adopt the Schneider Brands

The main motors adopt the Taiwan Brands

GF-T Glue Making System

Machine Introduction:

1. Supply starch adhesive for single facer(s) and gluing machine. Automatic recycle type.

2. Horizontal mixer could confects the main glue and carrier glue and then mix them enough with large volume.

3. Glue pump transport the glue from glue making storage pot, supply enough glue for each single facer and gluing machine.

4. The storage pot and supply pot all equipped with mixing device, preventing glue from depositing.

5. Glue making part include Carrier pot, main pot, storage pot, supply pump and return pump

6. Adopts automatic recycle supply glue, surplus glue return to the glue pot, automatic glue level control, the return pumped to the storage pot with self-pump, do automatic self-circle, avoiding glue gelling and solidifying in the glue pan.

After finish manufacture, surplus glue returns to glue pot for next time to use.

7. Manufacturer supply gluing making

Pneumatic system

Supply compressor air for every pneumatic devices in the whole production line and keep the stable working pressure.

1. Centralized air supplying with air compressing station.

2. Compressed air filtered at the inlet is clean and stable.

3. Individual control of each unit independently of each other

4. Adjustable pressure with pressure meter for each unit

5. Accessorial copper pipes and PV pipes are wearable.

6. Re-filtered and lubricated with oil mist prior to entering each machine

7. Integrated pneumatic and electric control system with one operation panel, featuring easy and convenient remote operation.

EF-T Electric system

System Introduction:

1. Main control part included single facer(s), double facer, slitter scorer, NC cutoff; make whole production line coordination control

2. Pneumatic control and electric control composed ensure whole line control's technical advancement.

3. Each machine group all had independent control and coordination control two system, could meet different requirements in separately operate or combine operate. Easy for operate.

4. Production line equipped with alarm system, coordinate the work between the operators.

5. Each machine all could show other separately machine's working speed.

6. Electric parts made in Schneider brand

SP-S Steam system

Specification:

Steam computation: 2t/h

Boiler: 4ton

Boiler pressure: 1.25Mpa

Pipeline inner temperature: 160-200 centigrade

Steam pressure: 1.25Mpa

Each pipe entrance and exit diameter: 48mm, 32mm

Pre-heater entrance and exit diameter: ¢48mm, ¢32mm

Triplex pre-heater entrance and exit diameter: ¢48mm, ¢32mm

Double glue machine: ¢48mm, ¢32mm

Double facer (Drying and Finalizing Unit) entrance and exit diameter: ¢48mm, ¢32mm

System Introduction:

1. Supply heating source for whole production line, ensure temperature and pressure stable.

2. Each machine group supply steam separately independent, easy to adjust and save energy.

3. Adjusted the pressure to control work temperature, with meter to watch details.

4. Each drain unit with emptying device, make the cool after finish manufacture.

5. Each pipe adopts seamless steal pipe, ensure safety in manufacturing.

6. Each pipe surface lacquering anti-rust paint and aluminum powder, do stain proofing treatment.

Raw materials

1. metal hose, rotary joint: made in China

2. drain valve: made in China

Contact us if you need more details on Cardboard Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Production Line、Cardboard Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : 3 Ply Cardboard Production Line